The Plan-Do-Check-Act (PDCA) cycle serves as a foundational framework for structured, data-driven continuous improvement. However, to maximize its impact, integrate complementary methodologies at each stage of the cycle. This article explores how you can enhance PDCA with Root Cause Analysis, Agile Execution, Visual Management, Standard Work, and Kaizen Events, all supported by Gemba Walks to ensure alignment with operational realities.

Plan: Identifying and Addressing the Right Causes

Many improvement initiatives fail not because of poor execution, but because they target symptoms rather than root causes. The Plan phase is critical in ensuring that the right problems are being addressed.

- Utilize Root Cause Analysis techniques like the 5 Whys and Fishbone Diagrams to uncover the fundamental issues rather than applying quick fixes.

- Involve cross-functional teams in problem identification to ensure diverse perspectives and deeper insights.

- Clearly define success criteria and key performance indicators (KPIs) to measure the impact of changes.

Personal Experience: In the adoption of a new digital tool, a constant flow of tickets were raised for additional reports. The root cause was not that reports were missing, but people did not trust the data and tried to get reports to show this. Creating more reports is therefor not the solution, building trust in the data is.

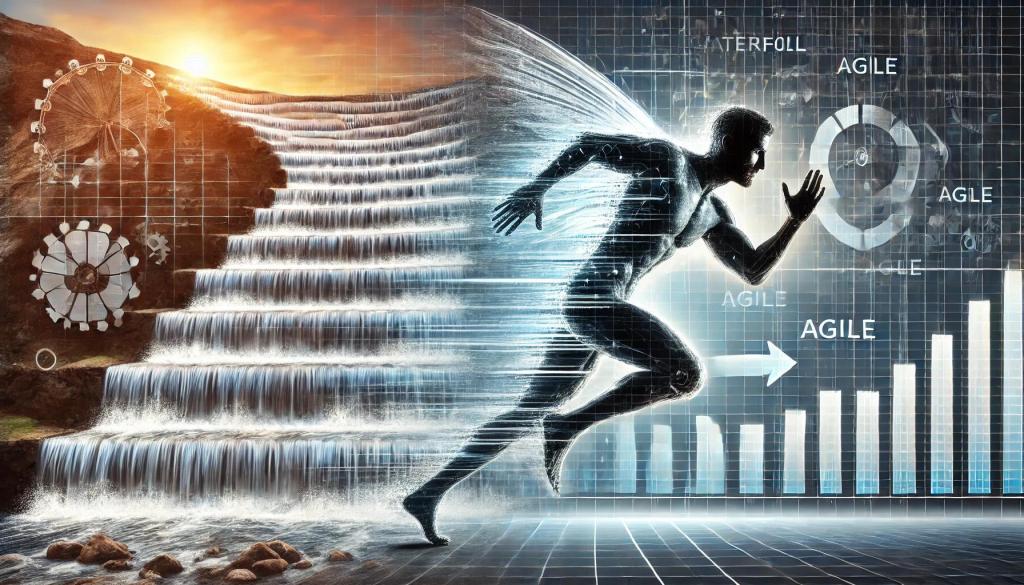

Do: Implementing Fast, Iterative Improvements Using Agile

Traditional improvement initiatives often fail due to long implementation cycles that do not adapt to emerging insights. In the Do phase, an Agile approach enables teams to execute improvements iteratively, ensuring quick learning and adaptation.

- Break down solutions into small, incremental changes rather than large-scale, disruptive overhauls.

- Use short sprints to test hypotheses, gather feedback, and refine the approach dynamically.

- Foster a culture of empowerment by enabling frontline employees to take ownership of improvements within their domain.

Personal Experience: Especially shortly after Go Live, people experience all kinds of issues in working with the new system. Logging the issues for the next big release might be tempting from a program perspective, but you lose both the momentum in adopting the solution as well as the business/process performance will lag behind.

Check: Leveraging Daily and Visual Management

Without structured reflection and analysis, even well-intentioned improvement efforts risk failure. The Check phase ensures that the changes implemented are having the desired effect and allows for course corrections.

- Implement Daily Management Routines, such as stand-up meetings, to assess progress and identify real-time roadblocks.

- Utilize Visual Management Tools like performance dashboards and Kanban boards to provide clear visibility into key metrics.

- Conduct regular reviews to assess whether improvements align with strategic objectives.

Personal Experience: Daily management in combination with clear, trustworthy dashboards is one of the most impactful concepts to drive the adoption, performance, and engagement of the teams. It fosters fast feedback and helps to accelerate the PDCA cycle.

Act: Standardizing or Pivoting Based on Results

The final phase of the PDCA cycle ensures that improvements either become standard practice or trigger deeper exploration through structured problem-solving.

- If the improvement proves effective, incorporate it into Standard Work to sustain the gains.

- If the problem persists, go deeper by organizing Kaizen Events—intensive, collaborative workshops aimed at breakthrough improvements.

- Ensure knowledge sharing so that lessons learned from one cycle inform future improvements across the organization.

Personal Experience: Evaluating what works and does not work can be done in different ways, but the important thing is that action is taken—to either sustain and spread the working solution or pivot. When the improvement did not work, it likely requires more analysis and review, and the Kaizen approach can really help here.

The Role of Gemba Walks: Ensuring Alignment with Reality

Supporting this entire PDCA cycle is the practice of Gemba Walks, where leaders go to the actual workplace (Gemba) to observe, engage with employees, and understand challenges firsthand. This prevents a disconnect between strategy and execution, ensuring that improvement efforts are grounded in operational realities.

- Ask open-ended questions to frontline employees to uncover hidden inefficiencies.

- Reinforce a culture where continuous improvement is not top-down but co-created with those closest to the work.

- Identify systemic barriers that require leadership intervention to remove.

Personal Experience: By going to the Gemba, leaders both get a better understanding of what is really happening and show commitment to their teams in leading the transition.

Conclusion: Continuous Improvement as a Leadership Imperative

PDCA, when enhanced with Root Cause Analysis, Agile Execution, Visual Management, Standard Work, Kaizen Events, and Gemba Walks, becomes a powerful engine for continuous improvement. Transformation leaders must champion this approach, ensuring that improvement is not a one-time initiative but a deeply embedded organizational capability.